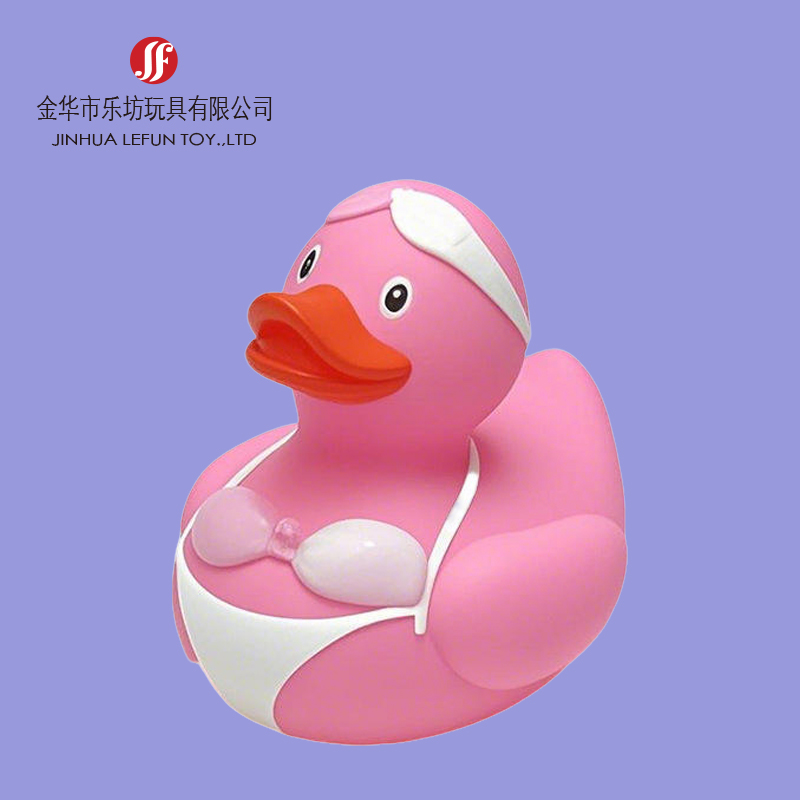

Custom vinyl pvc duck

We source and compound our vinyl PVC with a unwavering commitment to safety and performance, ensuring our duck toys are suitable for children and impactful for brands.

Non-Toxic, Phthalate-Free, and Child-Safe: Safety is our foremost priority. Our Vinyl PVC Duck Toy material is formulated to be 100% free from lead, BPA, and regulated phthalates (like DEHP, DBP, BBP). We utilize non-toxic plasticizers and stabilizers that comply with the most stringent international toy safety regulations, including CPSIA (USA), EN71 (EU, including specific migration limits for phthalates), ASTM F963, and FDA guidelines. Each production batch can be supported by laboratory test reports, providing assurance for retailers and parents alike.

Excellent Durability, Puncture & Tear Resistance: Vinyl PVC, when properly formulated, offers remarkable resilience. Our ducks are highly resistant to punctures, tears, and cracks, even when squeezed, bitten, or accidentally stepped on. The material’s inherent flexibility allows it to absorb impact and return to its original shape, ensuring a long lifespan through active play in the bath, pool, or nursery.

Superior Water & Chemical Resistance: Specifically designed for aquatic environments, our vinyl PVC compound exhibits outstanding resistance to water absorption, chlorine, and soap residues. It will not become waterlogged, degrade, or develop mildew inside. This makes it the ideal, hygienic material for a bath toy, as it can be easily cleaned and dried.

Vibrant, Long-Lasting Colors and Glossy Finish: The vinyl PVC material is exceptionally good at holding vibrant, opaque colors. Pigments are fully integrated into the compound, resulting in rich, fade-resistant hues that do not peel or wash off. Our ducks feature a characteristic smooth, glossy finish that is visually appealing and pleasant to the touch, maintaining its “like-new” shine through repeated use.

Perfect Buoyancy and Squeezable Softness: Through precise control of material density and wall thickness, we achieve the iconic perfect buoyancy and satisfying soft, squeezable feel that defines a classic rubber duck. The hollow body provides a gentle, air-filled squeeze and a cheerful squeak (when equipped), delivering timeless tactile and auditory feedback.

Unlike typical solid injection-molded toys, authentic vinyl duck toys are created using the rotocasting (rotational molding) process. This method is key to achieving the hollow, seamless, and durable structure.

Phase 1: Design & Master Model Creation (7-14 Business Days)

We begin by sculpting a precise, oversized master model of your duck design, typically from clay or digital 3D print. This model accounts for the material shrinkage that occurs during cooling. The design is optimized for the rotational molding process to ensure even wall thickness and proper detail definition on the final hollow toy.

Phase 2: Aluminum Mold Fabrication (20-35 Business Days)

The approved master model is used to create a two-part, hollow aluminum mold. Aluminum is preferred for its excellent heat conductivity, which is crucial for the rotocasting process. The interior surface of the mold is finely polished to impart a smooth finish to the toy. This is a critical and time-intensive stage that defines the quality of every subsequent duck.

Phase 3: Liquid PVC (PVC Paste) Preparation

We prepare a liquid vinyl PVC plastisol, a suspension of PVC particles in plasticizer. This liquid compound is carefully measured and injected into the pre-heated aluminum mold cavity. The specific formulation of the plastisol determines the final toy’s softness, color, and physical properties.

Phase 4: Rotational Molding (Rotocasting) & Curing

The filled mold is then closed and transferred to a rotational molding oven. It is heated while rotating slowly on two axes (biaxially). This rotation ensures the liquid PVC evenly coats the entire interior surface of the mold, forming a consistent, hollow shell. The heat cures the PVC, transforming it from a liquid into a solid, flexible vinyl layer.

Phase 5: Cooling, Demolding, and Trimming

After curing, the mold is moved to a cooling station. Once cooled, the mold is opened, and the hollow vinyl duck is removed. The toy is then meticulously trimmed by hand to remove any excess material (flash) from the seam, resulting in a clean, nearly invisible parting line.

Phase 6: Quality Inspection, Sound Module Insertion & Leak Testing

Each duck undergoes visual inspection. For squeaker models, a non-removable, air-pass squeaker is securely installed in the base. Every toy is then air-pressure tested to ensure it is completely airtight and will not take on water, guaranteeing safe buoyancy and function.

Total Project Timeline: For a new custom Vinyl PVC Duck Toy design, the standard lead time from master model approval to shipped goods is 60-80 calendar days. For reorders using existing molds, production can be completed in 30-45 days.

We specialize in transforming the universal appeal of the classic duck into a distinctive branded asset or specialized product line.

Full Design Customization:

Shape & Style: While the classic duck is iconic, we can create variations: different poses (swimming, waddling), themed ducks (sailors, superheroes, holiday characters), or even incorporate your company mascot into a duck-inspired hybrid design.

Size Range: Produce ducks in a wide array of sizes, from tiny party favor mini-ducks (under 2 inches) to giant promotional display ducks (over 12 inches).

Vibrant Color & Finish Options:

Unlimited Color Matching: We match any Pantone (PMS) color for perfect brand alignment.

Special Effects: Create glow-in-the-dark ducks, metallic finishes, sparkle/glitter-infused vinyl, or sophisticated matte coatings.

Decal Application: Apply detailed, waterproof decals for complex logos, facial features, or outfits that are difficult to achieve with mold color alone.

Functional & Interactive Features:

Squeaker Options: Choose from various squeaker tones or opt for a silent model.

Float & Balance Engineering: Customize weight distribution for perfect upright floating.

Water Squirters: Integrate a small hole to function as a bath squirter toy.

Educational Elements: Mold numbers, letters, or shapes onto the duck for bath-time learning.

Custom Packaging for Every Need:

We design packaging that enhances appeal and communicates your message:

Blister Cards & Clamshells: Retail-ready packaging with vibrant graphics, perfect for shelf display.

Tagged Poly Bags: Simple, cost-effective packaging for bulk promotions, weddings, or event favors.

Gift Boxes & Display Tubes: Premium packaging for collectible or high-end gift lines.

Bulk Shipping Cartons: Custom-printed cartons for large-scale corporate orders or distributor shipments.

Low MOQ and Scalable Production:

We support startups and global brands alike with flexible Minimum Order Quantities, making custom vinyl duck toys accessible for niche markets and large-scale promotional campaigns.

Float Your Brand with a Timeless Classic

The Vinyl PVC Duck Toy is a universally loved product with unparalleled cross-generational appeal. By combining a safe, durable material with specialized craftsmanship and deep customization, we offer a powerful tool for brand engagement, retail sales, and joyful play.

Contact our team today to discuss your custom vinyl duck project, request material safety documentation and samples, or receive a detailed quotation. Let’s collaborate to create your own iconic custom rubber duck that makes a splash in your market.