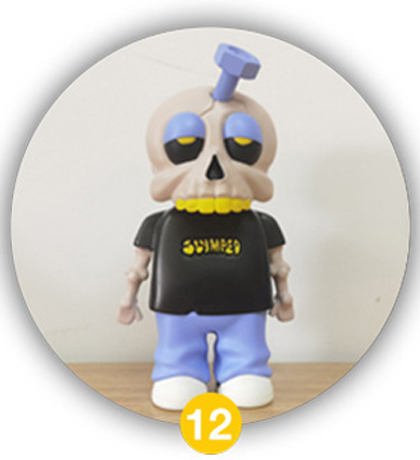

Toy tie

Our core strength

JinHua JoyFun Toy Co., Ltd., established in 2009, is a leading professional manufacturer specializing in the design, development, and production of high-quality figurines, toys, promotional gifts, and a diverse range of OEM and ODM orders. Strategically located in Jinhua City, Zhejiang Province—a key industrial hub with excellent logistics connections—our modern manufacturing facility spans 11,000 square meters. We adhere to the most rigorous international safety standards, including full compliance with European Directive 2009/48/EC on Toy Safety and 2001/95/EC on General Product Safety, ensuring every product delivers outstanding quality and peace of mind. With a dedicated workforce of over 150 skilled employees, we take pride in achieving annual sales exceeding USD 7 million. Currently, 95% of our products are exported to discerning clients across the globe, with strong market presence in Spain, Italy, Germany, France, the USA, and Japan.

Our development concept

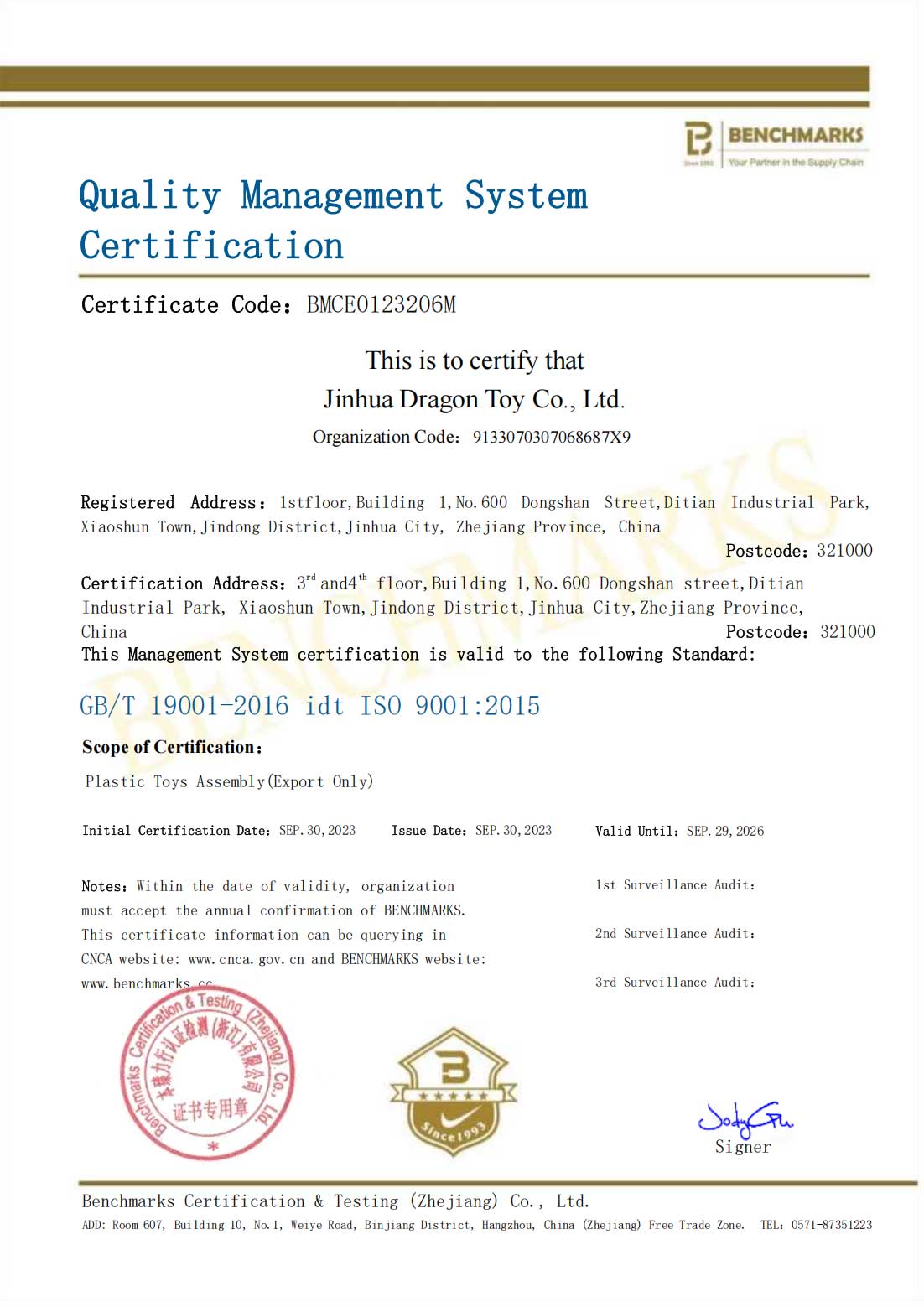

Our production efficiency is supported by state-of-the-art equipment, including 20 injection molding machines (ranging from 160-ton to 280-ton models), 3 streamlined assembly lines, 8 spray painting lines, 5 automated spraying machines, and a full suite of packing solutions comprising 5 auto-packing machines, 30 manual packing stations, and 5 shrink wrapping machines. This infrastructure enables us to seamlessly execute both high-volume orders and intricate custom projects. Our commitment to excellence is reinforced by internationally recognized certifications such as BSCI, Sedex, ISO 9001, and ISO 14001, underscoring our dedication to social responsibility, ethical manufacturing, consistent quality management, and environmental sustainability. We emphasize continuous innovation and maintain a dynamic R&D team focused on developing cutting-edge products that align with evolving global trends. By integrating creative design with robust manufacturing capabilities, we deliver tailored solutions and build lasting partnerships with clients worldwide.

we are properly

organized

02

Floor Plan

03

3D Drawing

05

Spray paint

06

Pad printing

07

Assembly

08

Packaging

PROFESSIONAL TOY PRODUCERS

Founded

0

Injection Machines

0

Skilled Team

0 +

Global Export

0 %