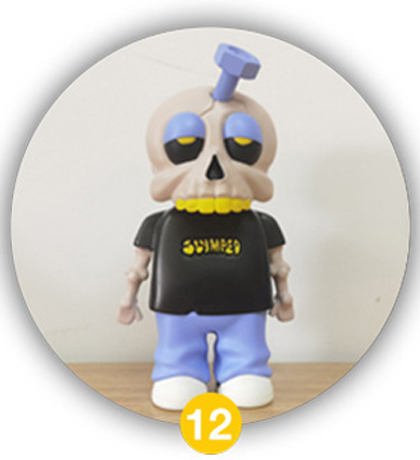

Finished Product

The completed toy, fully assembled, decorated, and packaged, is now ready for distribution. It represents the final output of the entire manufacturing chain, having passed all quality checks and conforming to the original design, aesthetic, and functional specifications.

Assembling & Packing

All manufactured and decorated components are gathered for final assembly. This may involve snapping parts together, using screws, or applying adhesives. Accessories are added, and the final product is placed into its packaging, which includes blister packs, clamshells, or boxes, along with any instruction manuals or cards.

Pad Printing

A process used for applying precise, high-detail graphics, logos, or fine line work onto the toy’s surface. A silicone pad picks up ink from an etched plate and transfers it directly onto the contoured or uneven surface of the toy. It is ideal for multi-colored designs that cannot be achieved with a single spray.

Spray Painting

This can refer to manual spray painting for touch-ups, complex shading, or effects that are difficult to automate. Skilled workers use airbrushes and masks to apply paint, adding detailed gradients, shadows, and other artistic nuances that enhance the toy’s depth and realism.

Auto-Spray Painting

An automated process where robot arms equipped with spray guns apply a base coat or primary colors to the toys. The parts are often placed on a rotating conveyor that passes through a spray booth. This method ensures a uniform, efficient, and consistent application of paint over a large volume of parts.

Painting Mould

For complex or multi-color paint applications, a separate set of specialized moulds or masks is created. These painting jigs hold the toy parts in place and have specific openings that allow paint to be applied only to designated areas, ensuring precision and consistency during the automated painting process.