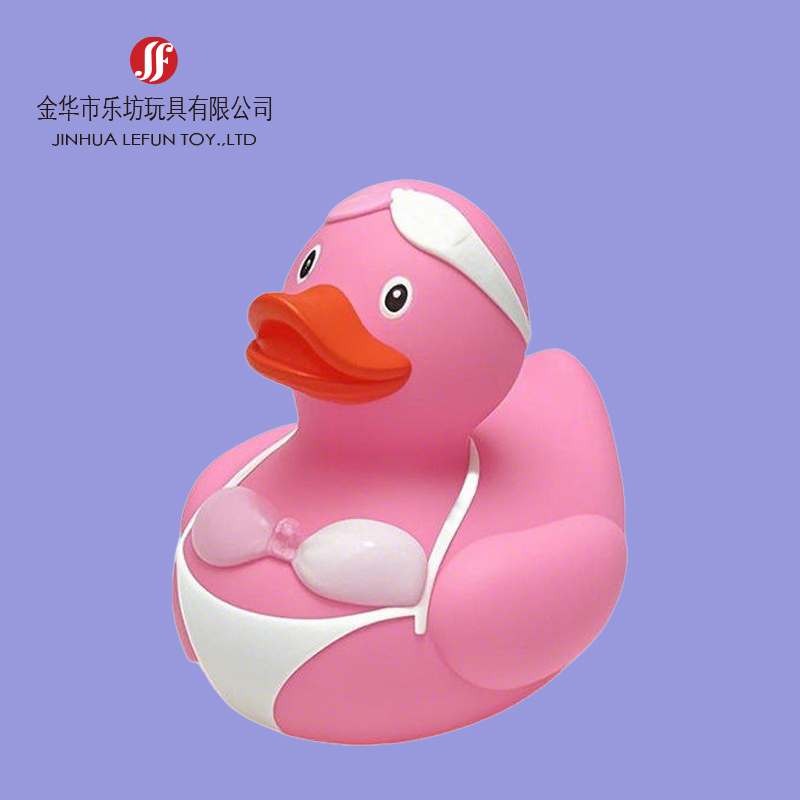

Custom vinyl pvc bathing toy

We begin with a commitment to safety and performance, utilizing a bespoke Vinyl PVC (Polyvinyl Chloride) compound formulated explicitly for bathing toys that must withstand water, chemicals, and enthusiastic play.

Non-Toxic, Phthalate-Free, and Globally Compliant: Safety is the non-negotiable foundation of our products. Our Vinyl PVC Bathing Toy material is meticulously formulated to be free from lead, BPA, and regulated phthalates (including DEHP, DBP, BBP). We utilize advanced, non-toxic plasticizers and stabilizers. Every batch is produced to meet or exceed the world’s most rigorous safety standards: CPSIA (USA), EN71-1, -2, -3 & specific migration limits for phthalates (EU), ASTM F963 (US), and FDA guidelines. We provide comprehensive test reports for our clients, ensuring seamless retail compliance and ultimate parent trust.

Exceptional Durability and Puncture Resistance: Bath toys face a demanding environment. Our vinyl PVC offers superior tear strength, puncture resistance, and overall structural integrity. The material is flexible and robust, capable of being squeezed, bitten, and dropped repeatedly without cracking, splitting, or losing its shape. This ensures the toy survives not just the bath but also the inevitable throws and chews of daily play, offering exceptional long-term value.

Superior Hydrolytic Stability and Chlorine Resistance: Unlike some materials that degrade in water, our PVC compound is engineered for excellent hydrolytic stability, meaning it does not absorb water, swell, or become waterlogged. It is highly resistant to degradation from chlorinated pool water and common bath soaps, preventing the material from becoming sticky or brittle. This also inhibits the internal growth of mold and mildew—a critical concern for bath toys.

Vibrant, Fade-Resistant Colors and Permanent Gloss: The aesthetic appeal is lasting. We use premium, internally mixed pigments that become an integral part of the material, resulting in bright, opaque, and ultra-durable colors that will not peel, flake, or wash off. Our toys feature a characteristically smooth, high-gloss finish that stays visually appealing and tactilely pleasant throughout the product’s lifespan, resisting hazing or dulling from constant water exposure and cleaning.

Perfect Buoyancy and Satisfying Tactile Feedback: Through precise density control, we achieve excellent, reliable buoyancy. The hollow construction, a hallmark of the rotational molding process, provides a uniquely satisfying soft, squeezable feel that is gentle on hands yet engaging for little fingers. This combination of buoyancy and squeezability defines the classic, beloved bath toy experience.

Authentic, hollow vinyl bath toys are created through rotational molding (rotocasting), a specialized technique that guarantees seamless, durable, and consistent products. We have mastered this art.

Phase 1: Design & Prototyping (8-15 Business Days)

Your journey begins with a concept. Our design team transforms your idea—be it a classic animal, a popular character adaptation, or an original creature—into a 3D model and then a physical master pattern. This pattern is sculpted to precise dimensions, accounting for the material shrinkage that occurs during manufacturing. We focus on designs that ensure even wall thickness and optimal detail for the molding process.

Phase 2: Precision Aluminum Mold Manufacturing (25-40 Business Days)

This is the most critical investment. The approved master pattern is used to craft a two-part, hollow aluminum mold. Aluminum is chosen for its superior heat transfer properties, essential for uniform curing. The interior cavity is polished to a mirror finish, which imparts the toy’s smooth surface. The quality of this mold defines the detail, consistency, and longevity of your entire production run.

Phase 3: Liquid PVC (Plastisol) Compounding & Coloring

We prepare a liquid vinyl compound known as PVC plastisol. This is where we integrate your specific color formulas, achieving perfect Pantone (PMS) matches or creating custom effects. The plastisol’s viscosity and formulation are calibrated for the desired wall thickness and final softness of the toy.

Phase 4: The Rotational Molding Process

A measured amount of liquid plastisol is injected into the pre-heated mold. The mold is then closed and transferred to a rotational oven. It rotates slowly on two axes (biaxial rotation) while being heated. This action coats the entire interior surface of the mold evenly with PVC, forming a consistent, hollow shell. The heat cures the liquid into a solid, flexible vinyl form.

Phase 5: Cooling, Demolding, and Finishing

After curing, the mold enters a cooling chamber. Once cooled, it is opened, and the hollow toy is carefully removed. Skilled artisans then perform meticulous hand-trimming to remove any excess material (flash) from the parting line, resulting in a clean, nearly seamless finish.

Phase 6: Rigorous Quality Assurance & Final Assembly

Each toy undergoes a multi-point inspection. For models with sound features, a non-removable, air-actuated squeaker is securely installed. Crucially, every single toy is pressure-tested to be completely airtight and waterproof, guaranteeing it will not sink or harbor internal moisture. They are then cleaned, dried, and prepared for packaging.

Total Project Timeline: For a new, custom Vinyl PVC Bathing Toy design, the standard lead time from finalized master pattern to shipped goods is 65-85 calendar days. For repeat orders using existing molds, production can typically be completed within 35-50 days, depending on order volume and complexity.

We transform the universal concept of a bath toy into a unique product that carries your brand’s identity, story, or promotional message.

Complete Design Freedom:

Original Sculpts: Create your own branded mascot, a series of thematic sea creatures, or educational shapes (letters, numbers).

Size Variety: Produce toys from tiny party favor sizes (1-2 inches) to large, impressive promotional “statement” toys (12+ inches) for displays or premium gifts.

Color & Aesthetic Customization:

Exact Color Matching: We guarantee precise PMS color replication for corporate identity projects.

Special Effects: Offer glow-in-the-dark toys for night-time fun, sparkle or glitter-infused vinyl, metallic sheens, or softer matte finishes.

Surface Decoration: Apply durable, waterproof heat-transfer decals or offset printing for complex logos, intricate facial details, or clothing designs that are not feasible through mold color alone.

Functional & Interactive Feature Integration:

Sound Modules: Integrate reliable squeakers, rattles, or even waterproof crinkle paper for varied auditory stimulation.

Water Squirters/Sprayers: Engineer toys with small holes to function as interactive squirters, enhancing bath-time play.

Interactive Elements: Design toys that connect, stack, or have moving parts (like spinning wheels).

Educational Components: Mold shapes, numbers, or animals in relief for tactile learning.

Tailored, Market-Ready Packaging:

We provide packaging solutions that protect, present, and sell:

Retail Clamshells & Blister Cards: Full-color, eye-catching packaging with product visibility, perfect for shelf appeal in supermarkets or toy stores.

Mesh Drawstring Bags or Ventilated Boxes: Practical packaging that allows the toy to dry after use, addressing parental concerns about mold.

Gift Boxes & Display Tubes: Elegant solutions for premium or collectible toy lines.

Poly Bags with Header Cards: Cost-effective and attractive for bulk promotional orders, hotel welcome kits, or event souvenirs.

Sustainable Packaging Options: Utilize recycled materials and minimal plastic design.

Flexible Business Models:

We cater to all business scales, offering competitive Minimum Order Quantities (MOQs) to make customization accessible for startups and established brands alike. Our dedicated project management ensures a smooth journey from concept to delivery.

Make a Splash with a Trusted Manufacturer

A Vinyl PVC Bathing Toy is a product category with timeless appeal and significant commercial potential. By partnering with us, you leverage expertise in safe materials, specialized manufacturing, and creative customization to develop a product that stands out in a crowded market.

Contact our customization team today to initiate your project, request material safety documentation and physical samples, or obtain a detailed quotation. Let’s collaborate to design and produce exceptional custom vinyl bath toys that delight children, satisfy parents, and float your brand to new heights of success.