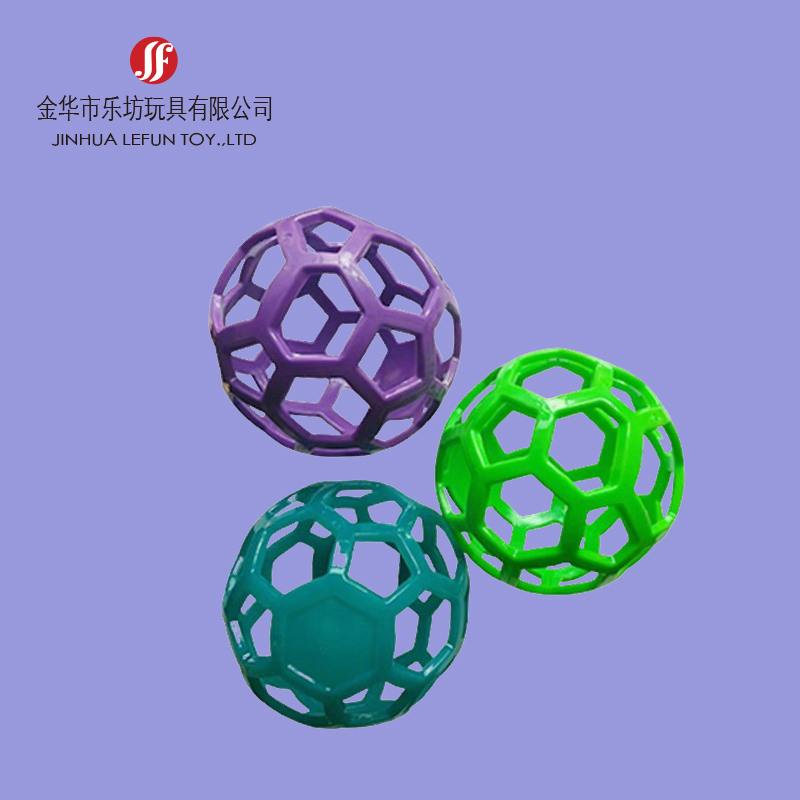

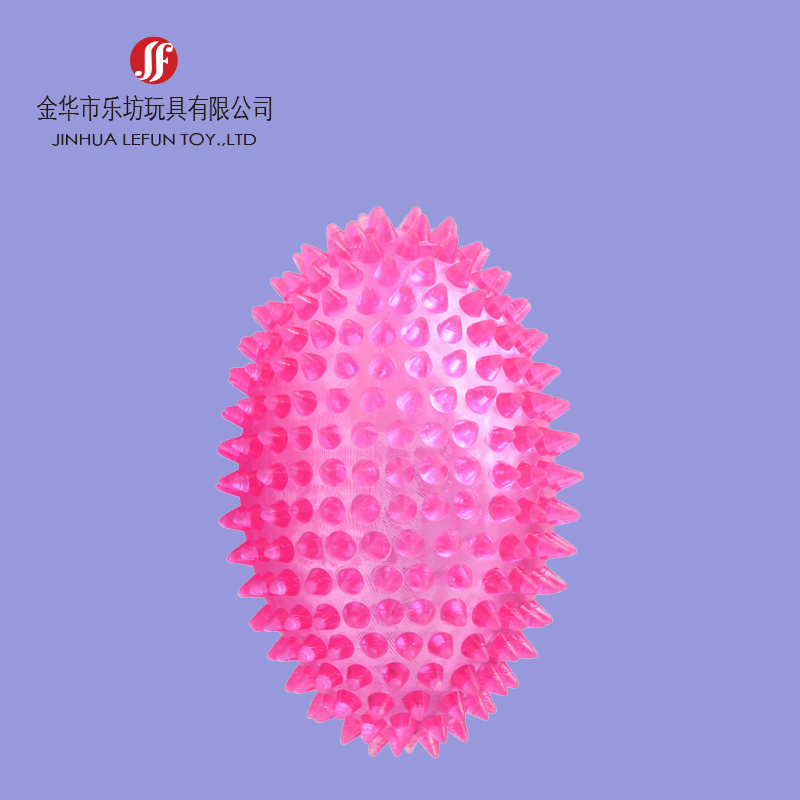

Custom vinyl pet toy

We begin with a material philosophy centered on pet wellness. Our Vinyl PVC compound is engineered from the ground up to be the optimal choice for durable pet toys.

Non-Toxic, Phthalate-Free, and Vet-Recommended Formulation: The safety of your customers’ pets is our highest priority. Our Vinyl PVC Pet Toy material is meticulously formulated to be 100% free from lead, BPA, and regulated phthalates (including DEHP, DBP, BBP). We utilize advanced, non-toxic plasticizers and stabilizers that are safe for prolonged contact. Our production complies with the most stringent global safety standards relevant to pet products, including FDA guidelines (for indirect food contact), EU REACH, CPSIA, and specific state regulations like California’s Prop 65. We provide comprehensive material safety data sheets (MSDS) and can arrange for independent lab testing to verify compliance for retail.

Exceptional Durability and Aggressive Chew Resistance: Designed for power chewers, our Vinyl PVC offers superior tensile strength, puncture resistance, and tear resistance. The material is flexible yet incredibly tough, allowing it to absorb and distribute the force of powerful bites without cracking, splintering, or breaking into dangerous shards. This “give and rebound” quality is crucial for dental health and significantly extends the toy’s lifespan compared to harder, more brittle plastics, providing exceptional value and safety.

Superior Hydrolytic Stability and Easy Hygiene: Pet toys encounter saliva, water, and dirt. Our PVC compound boasts excellent hydrolytic stability, meaning it does not absorb water or become waterlogged. Its non-porous, seamless surface (achieved through rotational molding) prevents bacteria, mold, and saliva from penetrating the toy’s interior. This makes it exceptionally hygienic and easy to clean—simply wash with mild soap and water or place in a dishwasher. This feature directly addresses a major concern for pet owners regarding toy hygiene.

Weather and Chemical Resistance for Indoor/Outdoor Play: Pets play everywhere. Our material is fortified with UV stabilizers and anti-oxidants to resist degradation from sunlight, ozone, and temperature extremes. It will not become brittle in cold weather or overly soft and sticky in heat. Furthermore, it is highly resistant to chlorine and saltwater, making our floating toy designs perfect for pool, beach, and outdoor adventures.

Vibrant, Long-Lasting Colors and Appealing Texture: We use premium, internally mixed pigments that create vibrant, fade-resistant colors integral to the material. The colors will not chip, peel, or wash off. The final toy has a smooth, glossy finish that is appealing to pets and owners alike, and the texture can be customized with ridges, nubs, or bristles to enhance dental cleaning efficacy and gum massage.

The hollow, uniform, and incredibly durable construction of our pet toys is achieved through rotational molding (rotocasting), a process ideal for creating seamless, stress-resistant products.

Phase 1: Design & Engineering for Pet Safety (10-15 Business Days)

Our process starts with your concept, guided by principles of pet safety and behavior. Our design team, knowledgeable in pet product standards, creates models optimized for durability and engagement. We ensure appropriate size, wall thickness, and shape, avoiding small, detachable parts. Designs are made for the rotational molding process, and a 3D model or physical prototype is created for your approval.

Phase 2: High-Durability Aluminum Mold Fabrication (25-40 Business Days)

This phase represents a critical investment in quality. An approved master model is used to create a two-part, hollow aluminum mold. Aluminum provides excellent heat transfer for uniform curing. The interior cavity is precision-machined and polished to create a flawless toy surface. The mold’s quality directly dictates the toy’s consistency and durability over a high-volume production run.

Phase 3: Liquid PVC (Plastisol) Compounding

We prepare a liquid vinyl PVC plastisol, customizing its formula to achieve the exact desired flexibility (Shore hardness), density, and color. This is where we integrate pet-safe colorants and any functional additives.

Phase 4: The Rotational Molding (Rotocasting) Process

A precise amount of liquid plastisol is injected into the heated mold. The mold is then closed and rotated slowly on two axes inside a heated oven. This rotation evenly coats the entire interior surface, forming a consistent, hollow shell. The heat cures the liquid into a solid, flexible vinyl form. This method creates a uniform wall thickness with no weak seams, which is key for chew resistance.

Phase 5: Cooling, Demolding, and Precision Trimming

The mold is cooled, opened, and the hollow toy is removed. Skilled technicians then perform meticulous hand-trimming to remove any excess material (flash) from the parting line, ensuring a smooth, safe edge that is comfortable for a pet’s mouth.

Phase 6: Rigorous Quality Assurance, Assembly & Testing

Each toy undergoes a multi-stage inspection. For toys with squeakers, a non-removable, air-activated squeaker is securely installed. Every single unit is air-pressure tested to guarantee it is completely airtight and waterproof, ensuring it will not sink or take on water. Finally, random samples from each batch undergo destructive chew-simulation testing to validate durability claims.

Total Project Timeline: For a new custom Vinyl PVC Pet Toy design, the standard lead time from finalized design to shipped goods is 70-95 calendar days. For repeat orders using existing molds, production can typically be completed within 40-55 days.

We partner with you to create distinctive products that capture market share and build brand loyalty in the competitive pet industry.

Bespoke Toy Design & Functionality:

Original Shapes: Design unique toys: from realistic prey animals and bone variants to interactive puzzle shapes and branded mascots.

Functional Focus: Specialize in dental care toys with deep-cleaning textures, treat-dispensing toys with hollow cavities or complex internal channels, fetch toys with perfect aerodynamic or buoyant properties, or tug toys with integrated rope ends.

Advanced Functional Customization:

Variable Chew Intensity: Customize the Shore hardness to create product lines for puppies, gentle chewers, and aggressive power chewers.

Integrated Features: Include treat pockets, built-in rope knots, durable squeakers of varying tones, rattles, or floating cores.

Scent Infusion: Impregnate the PVC with long-lasting, pet-safe, appealing scents (e.g., bacon, chicken, peanut butter) to instantly attract pets.

Textured Surfaces: Design specific ridges, nubs, or bristle patterns to maximize dental plaque removal.

Color, Scent, and Aesthetic Customization:

Brand Color Matching: Achieve exact PMS colors for consistent brand identity across product lines.

Visual Effects: Offer glow-in-the-dark toys for nighttime visibility, multi-color swirls, or translucent sections.

Printing & Decals: Apply durable, non-toxic printed graphics or heat-transfer decals for logos, patterns, or instructions.

Professional, Shelf-Ready Packaging:

We design packaging that educates, assures, and sells:

High-Impact Blister Cards & Clamshells: With clear product visibility, key selling points (“Durable Chew,” “Dental Health,” “Floatable”), breed/size guidance, and safety features highlighted.

Informative Poly Bags: Full-color, resealable bags with strong header cards, ideal for e-commerce or bulk sales.

Gift Sets & Multi-Packs: Create themed sets (e.g., “Puppy Teething Kit,” “Power Chewer Bundle”) in custom printed boxes.

Sustainable Packaging Options: Use recycled materials and minimal plastic design to appeal to eco-conscious consumers.

Flexible and Scalable Partnership:

We support brands of all sizes with competitive Minimum Order Quantities (MOQs) for custom projects, enabling market testing and niche product development. Our dedicated account management ensures a seamless path from concept to global distribution.

Build a Better Brand with a Superior Product

A Vinyl PVC Pet Toy developed with our expertise is more than an item; it’s a statement of quality, safety, and innovation in the pet space. By leveraging superior materials, specialized manufacturing, and deep customization, we deliver products that pets love, owners trust, and retailers confidently stock.

Contact our pet product specialists today to discuss your custom toy project, request material safety documentation and chew-test samples, or obtain a detailed quotation. Let’s collaborate to create the next must-have Vinyl PVC Pet Toy that drives engagement, ensures safety, and delivers outstanding ROI for your brand.